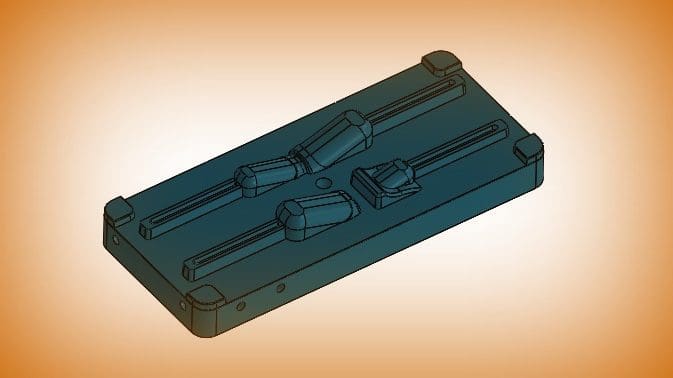

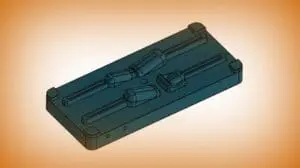

Reverse Injection Mold

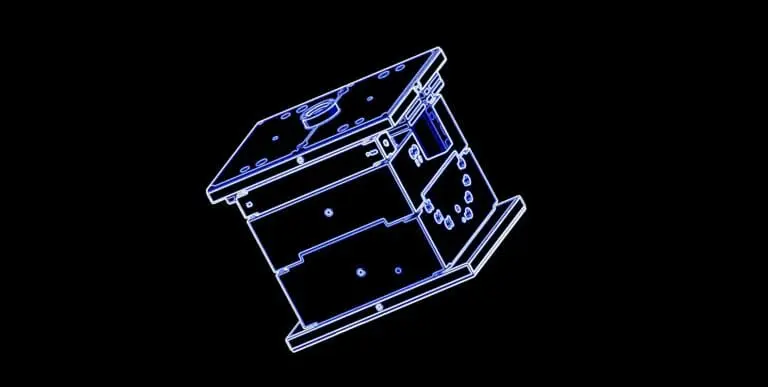

When discussing plastic injection mold construction, people sometimes refer to a “reverse mold.” What exactly does that mean, and how is a reverse mold different from a standard injection mold?

When discussing plastic injection mold construction, people sometimes refer to a “reverse mold.” What exactly does that mean, and how is a reverse mold different from a standard injection mold?

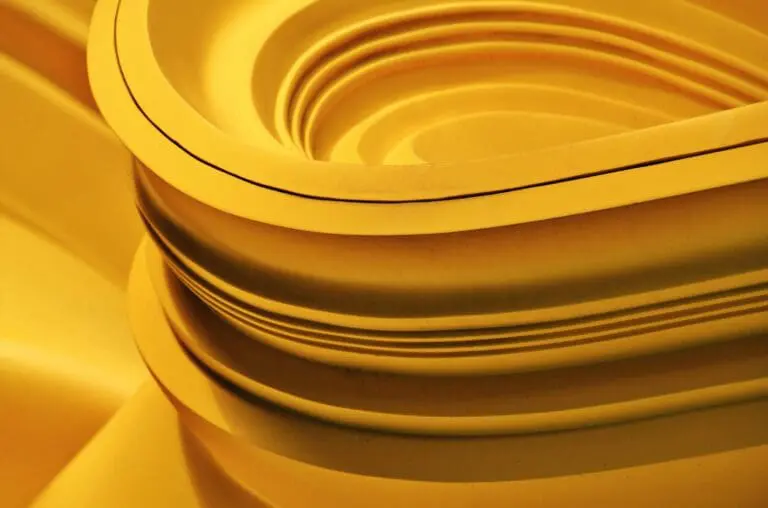

The plastics used for injection molding come in a variety of types, grades and compositions. When a resin meets most but not all the requirements of a product, certain additives can be used to add desired qualities to the material.

What exactly are bioplastics, how do they differ from traditional plastics, and what are the issues and options associated with them? Additionally, how do they fit into a modern ecologically-sound commercial framework?

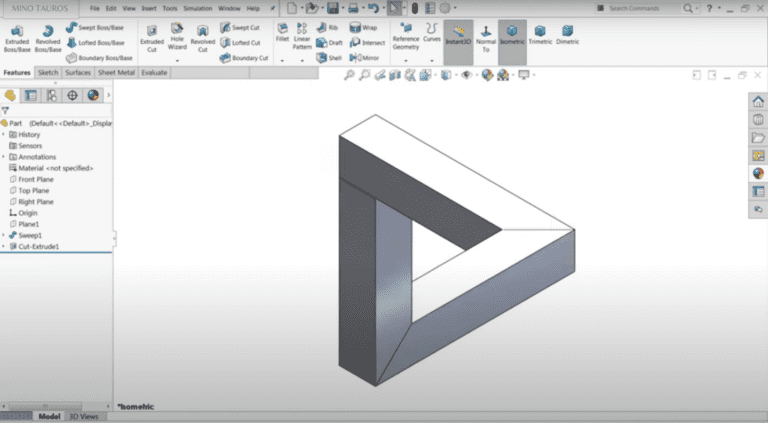

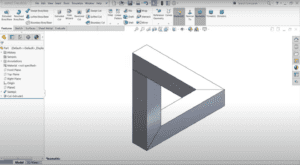

Changes in technology used for the design and manufacturing of plastic parts can make it challenging to keep things straight. Accordingly, what follows should serve as a simple introduction to the basics of modern computer part modeling and file types.

There are a variety of methods for decorating plastic parts, and each has certain advantages and considerations, depending on the part application, the decorating purpose, and the resin being used. Here’s a quick summary of the most common techniques.

Determining the best approach toward purchasing materials from your suppliers can be challenging. Luckily, there’s a relatively straightforward method for calculating the optimal frequency and amount of goods to order to maintain and replenish inventory in a cost-effective manner.

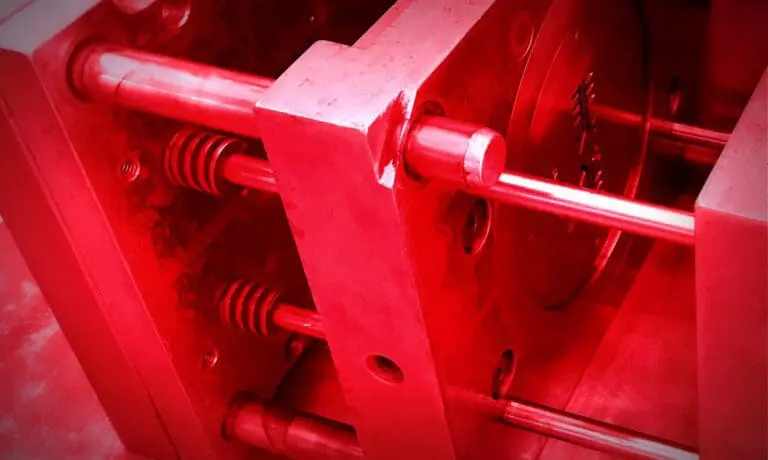

What are the tooling options for similar but differing parts? Of course, you can’t change the size or configuration of a steel mold… Or, can you?

While all manufacturing programs are different, what are reasonable expectations for how long certain tasks should take? Here’s an overview of some standard lead times for common elements of the mold building and injection molding process.

In addition to manufacturing, some plastic injection molders also provide assembly services. While there are different types of product assemblies, a standard approach for determining what the process will entail is referred to as performing a time and motion study.

When a new injection mold is built, it usually goes through two general stages of testing and evaluation. These phases serve somewhat different purposes, although they are related, and both are necessary for the mold to be ready for production.

When discussing plastic injection mold construction, people sometimes refer to a “reverse mold.” What exactly does that mean, and how is a reverse mold different from a standard injection mold?

The plastics used for injection molding come in a variety of types, grades and compositions. When a resin meets most but not all the requirements of a product, certain additives can be used to add desired qualities to the material.

What exactly are bioplastics, how do they differ from traditional plastics, and what are the issues and options associated with them? Additionally, how do they fit into a modern ecologically-sound commercial framework?

Changes in technology used for the design and manufacturing of plastic parts can make it challenging to keep things straight. Accordingly, what follows should serve as a simple introduction to the basics of modern computer part modeling and file types.

There are a variety of methods for decorating plastic parts, and each has certain advantages and considerations, depending on the part application, the decorating purpose, and the resin being used. Here’s a quick summary of the most common techniques.

Determining the best approach toward purchasing materials from your suppliers can be challenging. Luckily, there’s a relatively straightforward method for calculating the optimal frequency and amount of goods to order to maintain and replenish inventory in a cost-effective manner.

What are the tooling options for similar but differing parts? Of course, you can’t change the size or configuration of a steel mold… Or, can you?

While all manufacturing programs are different, what are reasonable expectations for how long certain tasks should take? Here’s an overview of some standard lead times for common elements of the mold building and injection molding process.

In addition to manufacturing, some plastic injection molders also provide assembly services. While there are different types of product assemblies, a standard approach for determining what the process will entail is referred to as performing a time and motion study.

When a new injection mold is built, it usually goes through two general stages of testing and evaluation. These phases serve somewhat different purposes, although they are related, and both are necessary for the mold to be ready for production.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786